Methodology

Line Cyclic Alkenes

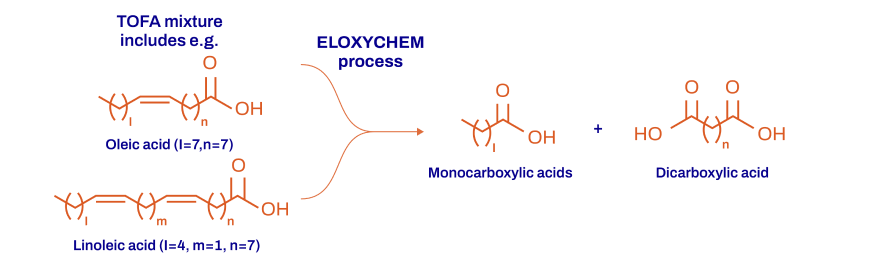

Line TOFA

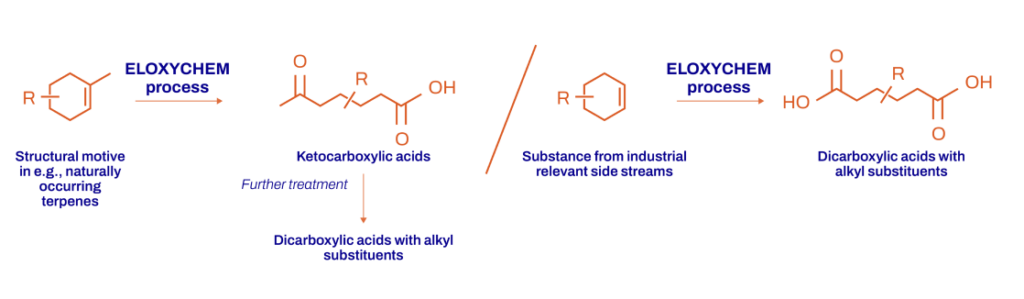

Line SIDES

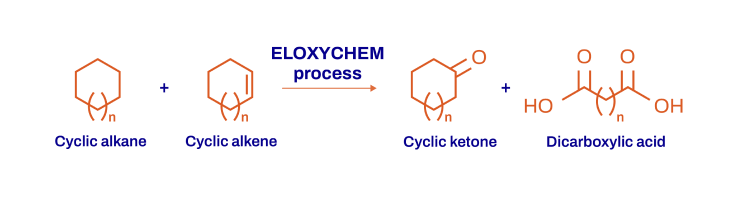

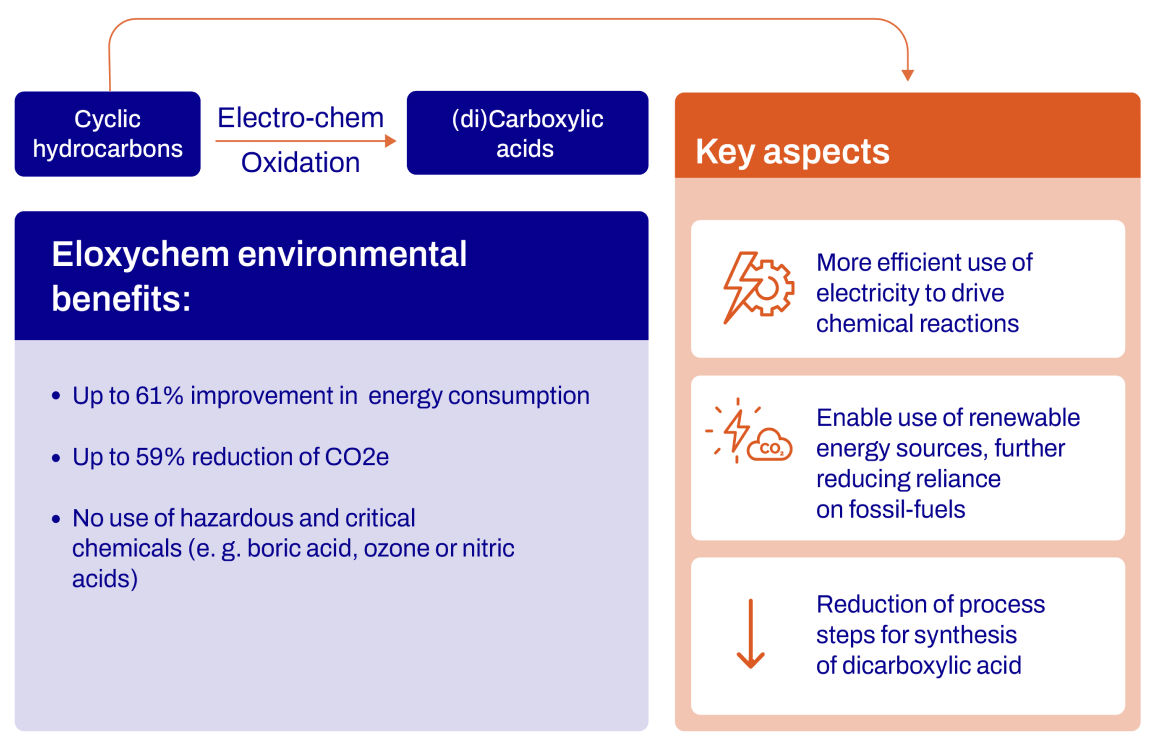

The ELOXYCHEM team will concentrate initially on the development and optimisation work on the transformation of one specific cyclic alkene which will be converted to an industry-relevant dicarboxylic acid. This diacid is used by the polymer industry for the production of high-performance polymers which are used in a wide range of applications for diverse markets – from automotive industry to consumer goods (e. g. sportswear). Furthermore, the parallel conversion of cyclic alkanes and cyclic alkenes will be investigated because in conventional processes alkanes can occur as by-products in the alkene production.

The co-produced cyclic ketones are valuable material and can be used for nylon synthesis. The cyclic alkene route will be scaled to pilot plant production. Additionally, the ELOXYCHEM team will investigate the conversion of industrial side streams and biogenic feedstocks in order to produce valuable chemicals.

Applications

- Sophisticated tubing systems for motor vehicles

- Pipes for crude oil production

- Cable industry

- Medical technology

- Precision injection-moulded parts

- Resins and coatings

ELOXYCHEM process

Expected results

Industrially feasible electrochemical oxidation processes

For the conversion of cycloalkanes and cycloalkenes to oxo-functionalisation products, including carboxylic acids and cyclic ketones

Energy efficiency gains and less energy intensive products

Scale-up of electrochemical processes from pilot to commercial scales

AI-based software for electrochemical oxidation processes based on a Digital Twin

Tools for optimised process control and monitoring

Integrating electrochemical oxidation processes with renewable energy sources (RESs)

Incorporating modelling and simulation tools